Name:

SLS nylon and nylon+GF sintering

Classification:

SLS nylon and nylon+GF sintering

Brand:

Lingying Model

Hotline:

021-69590699-127

Email:

zhengyong@jswzmx.com

Product Details

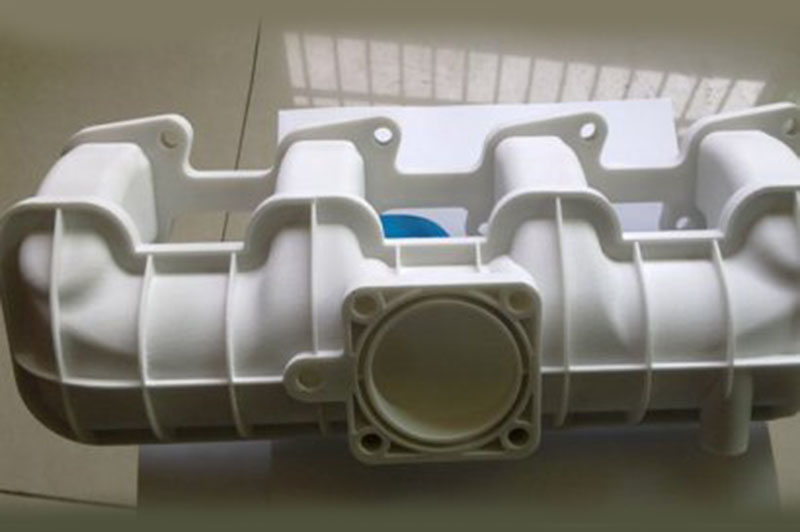

3D printing SLS (Selective Laser Sintering) process is also called selective laser sintering.

Processing principle:

The whole process unit is composed of a powder cylinder and a forming cylinder. When working, the piston (powder feeding piston) of the powder cylinder rises, and the powder is evenly spread on the piston (working piston) of the forming cylinder by the powder spreading roller. The computer controls the two-dimensional scanning trajectory of the laser beam according to the prototype slice model, and selectively sinters solid powder materials to form a layer of parts. After one layer of powder is completed, the working piston drops one layer thick, and the powder spreading system is paved with new powder. Control laser beam to rescan and sinter new layer. This is done in a circle, layer by layer, until the 3D part is formed. Recover the unsintered powder into the powder tank and take out the molded part. For metal powder laser sintering, before sintering, the whole worktable is heated to a certain temperature, which can reduce the thermal deformation in the forming process and facilitate the bonding between layers.

Features of SLS technology:

Compared with other 3D printer technologies, SLS stands out because it uses a wide range of molding materials. Theoretically, any powder material that can form atomic bonding after heating can be used as SLS molding material. At present, the materials that can be successfully processed by SLS include paraffin, polymer, metal, ceramic powder and their composite powder materials. SLS is used more and more widely because of the variety of SLS molding materials, material saving, wide distribution of molded parts' performance, suitability for multiple uses, and the need to design and manufacture complex support systems.

- Previous: SLS nylon and nylon+GF sintering

- Next: SLS nylon and nylon+GF sintering