Name:

SLS nylon and nylon+GF sintering

Classification:

SLS nylon and nylon+GF sintering

Brand:

Lingying Model

Hotline:

021-69590699-127

Email:

zhengyong@jswzmx.com

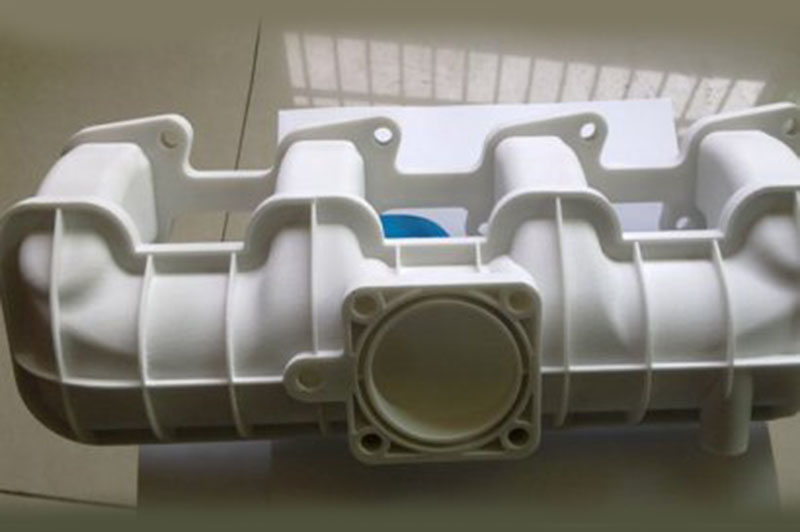

Product Details

SLS powder material selective sintering (SLS) is a rapid prototyping process, referred to as SLS. The selective sintering of powder materials adopts carbon dioxide laser to selectively sinter powder materials (plastic powder, mixed powder of ceramic and binder, mixed powder of metal and binder, etc.), which is a process method of integrating three-dimensional entities layer by layer from discrete points. Before processing, the working chamber filled with nitrogen shall be heated up and kept below the melting point of the powder. During forming, the feeding cylinder rises and the powder spreading cylinder moves. First, a layer of powder material is laid on the working platform, and then the laser beam is controlled by the computer to sinter the powder where the solid part is located according to the profile, so that the powder dissolves

The advantages of SLS rapid prototyping technology are:

1. Compared with other processes, it can produce hard moulds.

2. A variety of materials can be used, such as most engineering plastics, waxes, metals, ceramics, etc.

3. The construction time of parts is short, and the height can reach 1 in/h.

4. No post correction of parts is required.

5. No design and construction support is required.

The advantage of selective sintering is that a variety of materials can be selected, which is suitable for different purposes. The prototype products manufactured have high hardness and can be used for functional tests.

- Previous: SLS nylon and nylon+GF sintering

- Next: SLS