Name:

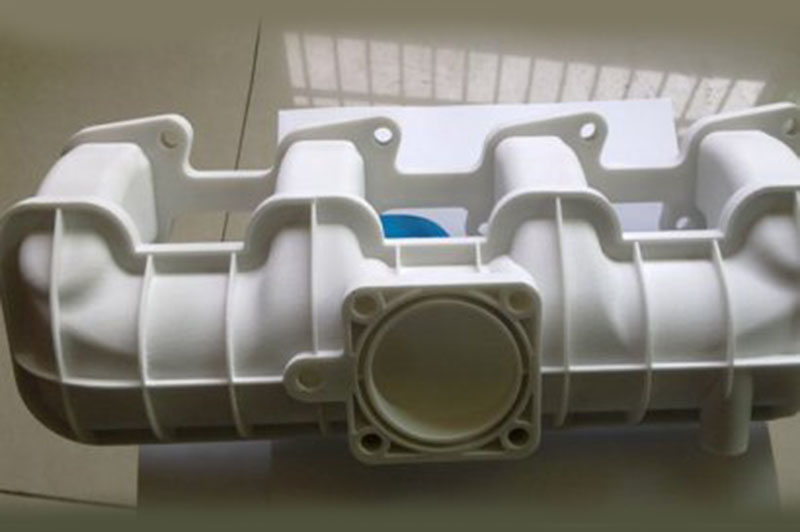

SLS nylon and nylon+GF sintering

Classification:

SLS nylon and nylon+GF sintering

Brand:

Lingying Model

Hotline:

021-69590699-127

Email:

zhengyong@jswzmx.com

Product Details

SLS nylon (glass fiber) is a 3D printing material used by printing customers. The nylon model is composed of off white and very fine powder particles. The product has high strength and certain flexibility, and can withstand small impact and slight bending. The surface of the model presents a frosted, granular appearance with slight permeability.

Technological advantages

Compared with other rapid prototyping processes, the selective laser sintering process is unique in that it can directly produce metal products. At the same time, the process also has the following advantages:

1) A variety of materials can be used. In principle, this method can use any powder material that is reduced annually during heating to make any shape through materials or various coating particles containing adhesives to meet different needs.

2) The manufacturing process is relatively simple. Due to the variety of materials available, the selective laser sintering process can directly produce complex shaped prototypes, three-dimensional components or parts of the cavity mold and tools according to the different raw materials used.

3) High precision. Depending on the type and particle size of the material used, the geometric shape and complexity of the product, the process can generally reach the overall scope of the workpiece± (0.05 - 2.5) mm tolerance. When the particle size of powder is less than 0.1mm, the prototype precision can reach± 1%。

4) No supporting structure is required. Like LOM process, SLS process does not need to design supporting structure, and the suspended layer in the process of lamination can be directly supported by unsintered powder.

5) High utilization rate of materials. As this process does not require a supporting structure, nor does it produce many wastes like LOM process, nor does it require the production of substrate support, the material utilization rate of this process method is high among several common rapid prototyping processes, which can be considered as 100%. Most of the powders used in the SLS process are cheap, so the cost of the SLS model is relatively low.

6) The production cycle is short. It only takes a few hours to dozens of hours from CAD design to the completion of parts processing. The entire production process is digitalized and can be modified and manufactured at any time. This feature makes it particularly suitable for the development of new products.

7) Combined with traditional process methods, it can realize rapid casting, rapid mold manufacturing, small batch parts output and other functions, injecting new vitality into traditional manufacturing methods.

8) Wide range of applications. Due to the diversity of forming materials, SLS process is suitable for a variety of applications, such as prototype design verification, mold master, investment casting, casting shell and core.

- Previous: Daimler air outlet

- Next: SLS nylon and nylon+GF sintering